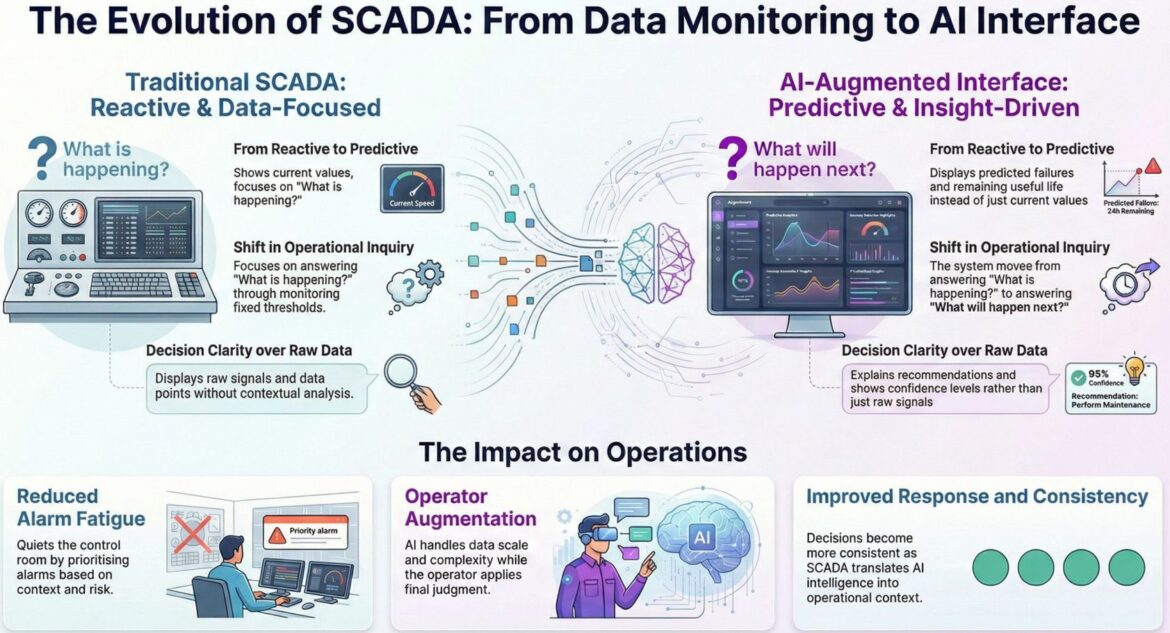

Industrial automation is undergoing a profound transformation, driven by the convergence of traditional Supervisory Control and Data Acquisition (SCADA) systems and advanced Artificial Intelligence (AI). For decades, SCADA systems served as the indispensable nervous system of industrial operations, diligently collecting data, displaying values, triggering alarms, and logging events. Operators, with their keen eyes and experience-honed judgment, would monitor screens, respond to alarms, and enact actions. This reactive model, while effective for its time, is rapidly evolving.

In the era of Industry 4.0, the role of SCADA is expanding dramatically. It is no longer merely a monitoring layer; it is becoming the crucial interface between human operators and the burgeoning power of AI. This shift fundamentally alters how industrial processes are managed, moving from a reactive “what is happening?” paradigm to a proactive, predictive “what will happen next?” approach. This article delves into this evolution, exploring the core changes, the underlying technologies, the operational impacts, and the strategic advantages of this new era of AI-augmented SCADA.

Understanding the SCADA Transformation: From Reactive to Predictive

The journey of SCADA from a data-focused, reactive system to an AI-driven, predictive interface is at the heart of modern industrial automation. This transformation redefines operational inquiry, the clarity of decision-making, and ultimately, the efficiency and resilience of industrial processes.

Traditional SCADA: Reactive and Data-Focused

For years, traditional SCADA systems were the backbone of industrial control. Their primary functions were clear and essential:

- Data Collection and Display: SCADA systems gathered vast amounts of data from sensors, programmable logic controllers (PLCs), and other devices across an industrial facility. This data—current speeds, temperatures, pressures, flow rates, and more—was then presented to operators on screens, often through graphical user interfaces (GUIs) that mimicked the physical layout of the plant.

- Alarm Generation: These systems were programmed with fixed thresholds. If a process variable exceeded or fell below a predefined limit, an alarm would be triggered, alerting operators to a potential issue.

- Event Logging: Every action, every alarm, every data point was meticulously logged, creating a historical record for analysis, compliance, and troubleshooting.

- Operational Inquiry: “What is happening?” The central question guiding traditional SCADA was, “What is happening right now?” Operators focused on monitoring current values and trends, often spending considerable time deciphering raw data to understand the current state of operations.

- Decision Clarity from Raw Data: In this model, decision clarity was derived directly from raw signals and data points. Operators were responsible for analyzing these raw inputs, identifying anomalies, and interpreting the implications without significant contextual analysis provided by the system itself. This required extensive experience and deep domain knowledge.

This traditional approach, while foundational, had inherent limitations. Operators frequently faced “alarm fatigue” due to a high volume of undifferentiated alerts. Diagnosis was left entirely to human operators, often after a problem had already manifested, leading to reactive maintenance and potential downtime.

AI-Augmented SCADA: Predictive and Insight-Driven

The advent of AI has propelled SCADA into a new era, endowing it with capabilities that move beyond mere monitoring to proactive prediction and insightful guidance. The integration of AI transforms SCADA into a powerful interface that augments human intelligence.

- Predictive Capabilities: Modern, AI-augmented SCADA systems are no longer limited to displaying current values. They can predict failures, estimate the remaining useful life of equipment, and anticipate deviations from optimal operational parameters. This is achieved by AI models that continuously analyze historical and real-time data, identifying subtle patterns that precede malfunctions.

- Contextual Anomaly Detection: Instead of just alerting on fixed thresholds, AI can explain why an anomaly was detected. It goes beyond saying “temperature is high” to “temperature is high because pump A is showing signs of bearing degradation, which is likely to lead to failure in the next 24 hours.”

- Prioritized Alarms: AI-driven SCADA can prioritize alarms based on context and risk. A minor deviation in a non-critical system might be deprioritized, while an impending failure in a critical asset receives immediate, high-priority attention. This significantly reduces alarm fatigue.

- Suggested Actions: Moving beyond simple alerts, the system can suggest specific actions to operators. This could range from “perform maintenance on pump A” to “adjust valve B by 10% to optimize flow.”

- Operational Inquiry: “What will happen next?” The focus shifts from merely understanding the present to predicting the future. AI-augmented SCADA helps answer critical questions like “What will happen next if we continue this operation?” or “What actions can prevent an impending issue?”

- Decision Clarity from Recommendations and Confidence Levels: Instead of requiring operators to sift through raw signals, the AI-augmented interface presents clear, actionable recommendations along with confidence levels. For instance, a display might show “95% confidence: Recommendation: Perform Maintenance,” providing transparent and trustworthy insights.

This evolution signifies a profound change in the human-machine collaboration within industrial settings. SCADA becomes less about raw data and more about decision clarity, enabling operators to make informed, proactive choices that enhance efficiency and prevent costly disruptions.

The Inner Workings: How AI Models Augment SCADA

The transformative power of AI-augmented SCADA lies in the sophisticated AI models that operate silently behind the scenes. These models are the intelligence engine, analyzing vast datasets and uncovering insights that would be impossible for humans to detect in real-time.

Analyzing Historical and Live Time-Series Data

AI models thrive on data. In the context of SCADA, this data comes in various forms:

- Time-Series Data: This is the continuous stream of measurements from sensors over time—temperature, pressure, vibration, current, voltage, flow rates, etc. AI algorithms are particularly adept at recognizing patterns and anomalies within these temporal sequences. Predictive maintenance models, for example, analyze how sensor readings change over time to detect early signs of equipment degradation.

- Historical Data: Years of operational data, including past equipment failures, maintenance records, production logs, and environmental conditions, serve as critical training data for AI models. By learning from past events, the AI can identify correlations and predict similar occurrences.

- Live Data Streams: Real-time data feeds from the SCADA system provide the immediate context for AI analysis. The models continuously process this live data against their learned patterns to detect emerging anomalies or predict future states.

Learning Normal vs. Abnormal Behavior

One of the foundational tasks of AI in SCADA is to establish a robust understanding of “normal” operational behavior. This is more complex than simply setting fixed thresholds:

- Dynamic Baselines: Normal operation is rarely static. It varies with load, environmental conditions, raw material inputs, and countless other factors. AI models, particularly those employing machine learning techniques like supervised and unsupervised learning, can learn dynamic baselines. They understand that a certain temperature might be normal under full load but abnormal under partial load.

- Pattern Recognition: AI can identify intricate patterns in data that signify healthy operation. For instance, the subtle interplay between vibration, temperature, and motor current might indicate optimal performance for a specific pump.

- Anomaly Detection: Once a model has learned normal behavior, it can effectively detect deviations. These anomalies are not just single data points outside a range, but often a combination of subtle changes across multiple parameters that, together, signify an impending issue. For example, a slight increase in vibration coupled with a minor temperature rise, even if both are individually within “normal” thresholds, could be flagged as abnormal by an AI.

Correlating Multiple Signals Across the Process

Industrial processes are complex, with interdependencies between numerous components and subsystems. A problem in one area can have ripple effects throughout the plant. AI excel at understanding these intricate relationships:

- Multi-Variate Analysis: Instead of analyzing each sensor independently, AI models can perform multi-variate analysis, considering dozens or even hundreds of sensor readings simultaneously. This allows them to identify correlations that human operators might miss or find too complex to process in real-time.

- Root Cause Analysis (Assisted): By correlating signals, AI can assist in identifying the potential root cause of an issue. If pressure drops in one pipe while a valve elsewhere shows unusual fluctuations, the AI can link these events, suggesting a possible blockage or malfunction in the valve.

- System-Wide Optimization: Beyond fault detection, correlating signals allows AI to optimize system-wide performance. For instance, adjusting the speed of multiple pumps and fan motors in a heating, ventilation, and air conditioning (HVAC) system based on real-time occupancy and external temperature data can lead to significant energy savings.

The interaction between operators and these complex AI models is not direct. Operators don’t “debug” the AI’s algorithm. Instead, the SCADA system acts as the intelligent translator, presenting the AI’s insights in a clear, comprehensible, and actionable format. This abstraction layers the complexity of AI, making its power accessible and useful to industrial personnel.

Redesigning the Human-Machine Interface: SCADA as the AI Face

The integration of AI fundamentally changes the design philosophy of SCADA interfaces. What was once about displaying raw data now revolves around delivering clarity, building trust, and augmenting human decision-making. SCADA becomes the human face of industrial AI, requiring specific design considerations.

Showing Confidence, Not Just Values

In an AI-augmented SCADA system, the display of data goes beyond mere numerical values. Operators need context around the AI’s recommendations.

- Confidence Scores: When an AI model predicts a failure or suggests an action, it should ideally present a confidence score (e.g., “95% confidence”). This metric allows operators to gauge the reliability of the AI’s insight, helping them decide how to weigh the recommendation against their own judgment and experience. A high confidence score instills greater trust, while a lower one might prompt further investigation.

- Probability of Failure: Instead of just an alarm, the system might display the probability of a specific component failing within a given timeframe (e.g., “Turbine #3 has a 70% chance of overheating in the next 12 hours”). This proactive information allows for planned intervention rather than reactive repair.

- Visual Uncertainty: Data visualization techniques can be employed to visually represent uncertainty or confidence. For example, a predicted trend line might have a shaded area indicating the confidence interval around the prediction, rather than just a single, definite line.

Explaining Recommendations, Not Hiding Them

Transparency is paramount for building operator trust. Operators are unlikely to blindly follow recommendations from a “black box” AI. The SCADA interface must explain the reasoning behind the AI’s suggestions.

- Contextual Explanations: When an AI recommends “Perform maintenance on Pump A,” the SCADA should provide a concise explanation such as “based on increased vibration amplitudes and elevated bearing temperatures detected over the last 48 hours, suggesting impending mechanical failure.”

- Key Contributing Factors: The interface can highlight the primary data points or anomalies that contributed to the AI’s conclusion. This could involve displaying a correlation matrix or a natural language summary of relevant sensor data.

- Traceability: Operators might need to click through to see the raw data supporting the AI’s finding, allowing them to validate the information if needed. This level of transparency reinforces trust and allows operators to learn from the AI.

Preserving Operator Authority and Override

AI is a tool to augment expertise, not replace it. The SCADA interface must be designed to empower operators, giving them ultimate control and the ability to override AI recommendations when necessary.

- Clear Override Mechanisms: It’s essential to have clear, intuitive controls that allow operators to accept, reject, or modify AI-suggested actions. This might involve a simple confirmation button for recommendations or a manual override switch for automated controls.

- Justification for Override: In some systems, operators might be prompted to provide a brief justification if they choose to override an AI recommendation. This serves as valuable feedback for both the system (potentially improving future AI models) and for auditing purposes.

- Human-in-the-Loop Design: The entire design philosophy should be “human-in-the-loop,” ensuring that operators always retain the final say, especially in critical safety or production scenarios. The AI acts as a highly intelligent assistant, not an autonomous dictator.

Maintaining Trust Through Transparency

Trust is the bedrock of effective human-AI collaboration. Without it, operators may hesitate to leverage the full potential of AI-augmented SCADA. Transparency is the key to building this trust.

- Clear Messaging and Language: The language used on the SCADA interface should be clear, concise, and unambiguous, avoiding technical jargon where possible for explanations of AI logic.

- Predictability of AI Behavior: As operators interact with the system, they should develop an understanding of how the AI behaves under different conditions. Predictable behavior builds confidence.

- Feedback Loops: Operators should feel that their feedback or overrides are considered by the system, leading to improvements over time. This can be as simple as acknowledging an override or providing summaries of how AI models are being updated based on operational input.

- Performance Metrics for AI: Displaying the performance metrics of the AI models themselves (e.g., accuracy rates, false positive rates) can further enhance transparency and trust, demonstrating the AI’s effectiveness.

By adhering to these design principles, SCADA interfaces can effectively bridge the gap between complex AI models and human operators, transforming raw data into clear, actionable intelligence and fostering a collaborative environment where technology elevates human capabilities. This makes SCADA less about displaying raw data and more about providing decision clarity.

The Transformative Impact on Operations

The integration of AI into SCADA systems brings about profound operational changes, fundamentally altering how industrial facilities manage alarms, augment their workforce, and improve response times and consistency. These impacts are not merely incremental; they represent a step change in operational efficiency and reliability.

Reduced Alarm Fatigue

Alarm fatigue has long been a significant challenge in control rooms. A deluge of undifferentiated alarms can desensitize operators, leading to missed critical alerts and increased stress. AI-augmented SCADA directly addresses this issue:

- Prioritization Based on Context and Risk: Instead of simply triggering an alarm for every deviation, AI analyzes the context (e.g., production phase, criticality of equipment, related sensor readings) and the potential risk associated with an anomaly. This allows the system to prioritize alarms, ensuring that operators are alerted first to issues that pose the greatest threat to safety, production, or equipment. For example, a minor fluctuation in a non-critical sensor might generate a low-priority notification, while an impending failure in a turbine’s lubrication system triggers an urgent, high-priority alarm.

- Suppression of Nuisance Alarms: AI can learn to differentiate between genuine anomalies and transient, non-critical fluctuations or expected variations during normal operations (e.g., a brief pressure spike during a valve actuation that is within safe operating parameters). By suppressing these “nuisance alarms,” the system significantly reduces the overall volume of alerts, allowing operators to focus on truly meaningful events.

- Root Cause Grouping: Instead of multiple alarms scattered across different systems all pointing to the same underlying problem, AI can group related alarms and present them as a single, higher-level event, often with an inferred root cause. This streamlines the operator’s diagnostic process.

- Control Room Quieter and More Efficient: The net effect is a control room that is “quieter” because SCADA shows only what truly matters. Operators spend less time sifting through irrelevant alerts and more time addressing critical issues, leading to calmer and more efficient operations.

Operator Augmentation

The term “operator augmentation” perfectly encapsulates the new relationship between humans and AI within industrial environments. AI doesn’t replace operators; it enhances their capabilities, allowing them to manage greater complexity and make more informed decisions.

- AI Handles Data Scale and Complexity: Modern industrial facilities generate enormous volumes of data—far too much for humans to process effectively in real-time. AI excels at crunching these massive datasets, performing complex statistical analyses, and identifying subtle patterns that indicate impending issues or optimization opportunities.

- SCADA Translates Intelligence into Operational Context: The SCADA system acts as the intermediary, transforming complex AI outputs (e.g., statistical probabilities, multi-variate correlations) into intuitive, actionable intelligence that operators can understand and utilize. It presents insights in a format that aligns with an operator’s conceptual model of the plant.

- Operators Apply Final Judgment: Crucially, the ultimate decision-making authority remains with the human operator. AI provides recommendations, predictions, and insights, but operators use their experience, domain knowledge, and understanding of external factors (which AI may not be privy to) to make the final, informed judgment. This ensures safety, accountability, and adaptability to unforeseen circumstances.

- Empowering Less Experienced Operators: By providing clear recommendations and contextual explanations, AI-augmented SCADA can empower less experienced operators to perform at a higher level, effectively encoding and disseminating institutional knowledge.

Improved Response and Consistency

The combination of predictive insights and augmented decision-making leads directly to faster, more consistent, and more effective operational responses.

- Faster Response Times: When operators are alerted to potential issues before they become critical, and are provided with clear recommendations, their response times drastically improve. Predictive maintenance (e.g., scheduling maintenance 24 hours before an anticipated failure) replaces emergency repairs, minimizing downtime.

- Consistent Decision-Making: AI provides objective, data-driven recommendations. This helps standardize decision-making processes across shifts and different operators, leading to more consistent operational outcomes. The system learns from past successful interventions (and less successful ones), refining its recommendations over time.

- Proactive Problem Solving: The shift from “what is happening?” to “what will happen next?” enables a fundamentally proactive approach to problem-solving. Issues are addressed during planned downtime or before they escalate, preventing costly incidents.

- Increased Trust in Automation: As operators witness the accuracy and effectiveness of AI-driven predictions and recommendations, their trust in the automation system grows. This increased trust fosters greater adoption and a more symbiotic relationship between humans and technology.

- Optimized Resource Allocation: With clearer insights into future performance and potential issues, managers can better allocate resources, schedule maintenance proactively, and optimize energy consumption, leading to significant cost savings and improved environmental sustainability.

The future control room, equipped with AI-augmented SCADA, will not necessarily be “quieter” due to a lack of data. Instead, it will be quieter due to efficient information processing—SCADA showing only what truly matters, allowing operators to focus their attention and expertise where it is most needed. This intelligent filtering and foresight lead to a more peaceful, yet highly productive, operational environment.

Key Technologies Enabling AI-Augmented SCADA

The evolution of SCADA into an AI interface is underpinned by several critical technological advancements. These technologies work in concert to collect, process, analyze, and present data in a way that empowers AI and, subsequently, human operators.

Edge Computing

One of the most significant enablers of AI in industrial settings is the rise of edge computing. This paradigm shift involves processing data closer to its source, rather than sending everything to a centralized cloud.

- Reduced Latency: For real-time industrial control, latency is a critical concern. Processing AI models directly on edge devices (such as industrial PCs, gateways, or even specialized controllers) significantly reduces the time it takes to analyze data and generate insights. This is crucial for applications like predictive control or fast anomaly detection where milliseconds matter.

- Enhanced Security: Transmitting sensitive operational data to the cloud introduces security vulnerabilities. Processing data at the edge reduces the amount of proprietary and critical data leaving the local network, enhancing cybersecurity for industrial assets.

- Offline Operation: Edge devices can continue to process data and run AI models even if connection to the cloud is temporarily lost. This ensures continuous operation and maintains the integrity of critical processes.

- Bandwidth Optimization: Sending raw, high-volume sensor data to the cloud can consume significant network bandwidth. Edge computing allows for pre-processing, filtering, and aggregation of data, sending only relevant insights or compressed data to the cloud for further analysis or storage, thus optimizing bandwidth usage.

- Localized Intelligence: Edge inference, where AI models run directly on-site, means that intelligence is embedded within the factory floor itself, allowing for faster, more autonomous responses.

Advanced AI Models

The sophistication of Artificial Intelligence models is central to the transformative power of AI-augmented SCADA. These models are the analytical engine.

- Machine Learning (ML): ML algorithms are the foundation, enabling systems to learn from data without explicit programming.

- Supervised Learning: Used for predictive maintenance, where historical data labeled with failure events trains models to predict future failures.

- Unsupervised Learning: Ideal for anomaly detection, as it can identify deviations from normal patterns in unlabeled data, flagging unusual behavior.

- Deep Learning (DL): A subset of ML, deep learning, particularly with neural networks, excels at recognizing complex patterns in very large datasets. This is valuable for:

- Complex Process Optimization: Identifying nuanced interactions between many variables to optimize overall plant performance.

- Image and Video Analysis: For quality control or safety monitoring, though less directly integrated with traditional SCADA data.

- Reinforcement Learning (RL): While less common in current SCADA implementations, RL holds promise for optimizing control strategies in dynamic environments. An RL agent could learn optimal control actions by trial and error, aiming to maximize a reward signal (e.g., energy efficiency, throughput).

- Natural Language Processing (NLP): Emerging applications include using Large Language Models (LLMs) to interpret incident logs, generate automated reports, or allow operators to query SCADA databases using natural language commands, simplifying interaction and data retrieval.

Cloud Computing and Hybrid Architectures

While edge computing handles real-time, localized processing, cloud computing still plays a vital role in AI-augmented SCADA, often in a hybrid architecture.

- Massive Data Storage and Processing: The cloud offers virtually unlimited storage and computational power, essential for storing vast historical datasets and training complex AI models that require significant resources.

- Global Visibility and Optimization: For multi-site operations, the cloud enables centralized data aggregation and analysis, providing a holistic view of overall performance and facilitating enterprise-wide optimization strategies.

- AI Model Development and Deployment: Many advanced AI model development platforms and Machine Learning Operations (MLOps) tools reside in the cloud, streamlining the process of building, training, and deploying AI models to edge devices.

- Scalability and Flexibility: Cloud infrastructure provides unparalleled scalability, allowing industrial operations to expand their AI capabilities as needed without significant upfront hardware investments.

- Hybrid Models: The most effective approach for many organizations is a hybrid model. Real-time control and immediate analysis happen at the edge, while long-term data storage, complex model retraining, and enterprise-wide analytics leverage the power of the cloud.

Open-Standard Architectures

The ability to integrate AI models seamlessly into existing SCADA infrastructure is heavily reliant on open-standard architectures.

- Interoperability: Modern SCADA systems are increasingly built on open standards like OPC UA (Open Platform Communications Unified Architecture), MQTT, and REST APIs. These standards facilitate seamless data exchange between SCADA, PLCs, sensors, Manufacturing Execution Systems (MES), enterprise resource planning (ERP) systems, and external AI platforms.

- Ease of Integration: An open architecture means that AI models developed in various programming languages (e.g., Python using libraries like TensorFlow or PyTorch) can be easily integrated. The SCADA system acts as the data conduit and the visualization layer, while specialized AI environments handle the complex computations.

- Future-Proofing: Open standards prevent vendor lock-in and ensure that SCADA systems can adapt to future technological advancements in AI and other industrial technologies. This flexibility is crucial for long-term strategic planning.

- Web Technologies: The migration of SCADA interfaces to web-based technologies allows for greater accessibility, easier deployment across various devices, and better integration with modern data visualization and analytics tools.

These technologies collectively form the bedrock upon which the next generation of industrial automation is being built, transforming SCADA from a data logger into a sophisticated AI interface.

Designing for Success: Best Practices for AI-Augmented SCADA Implementation

Implementing AI-augmented SCADA is a complex undertaking that requires careful planning and a strategic approach. To maximize the benefits and ensure a smooth transition, organizations should adhere to several best practices.

Step 1: Define Use Cases with Measurable ROI

Before embarking on any technological overhaul, it is imperative to clearly define the business problems that AI-augmented SCADA will solve and to quantify the expected return on investment (ROI).

- Focus on Pain Points: Start by identifying the most significant pain points on the factory floor. What causes the most unplanned downtime? Where are quality losses most prevalent? Which operations consume excessive energy? Where are manual interventions most frequent due to missing early signals? These are the areas where AI can deliver the most immediate and impactful value.

- Collaborate with Operations: Involve operators, maintenance staff, and production leads in this initial phase. Their on-the-ground experience is invaluable in identifying critical issues and understanding the nuances of current workflows.

- Narrow, Testable Use Cases: Translate broad problems into narrow, testable AI use cases. For example, instead of “improve maintenance,” define “predict compressor bearing failures using vibration and temperature data” or “detect anomalies in energy consumption during batch processing.”

- Hard Metrics for Success: Each use case must be tied to a clear, measurable metric. These could include:

- Downtime reduction (e.g., 15-25%)

- Reduction in energy consumption (e.g., 5-10%)

- Increased overall equipment effectiveness (OEE)

- Improved product quality (e.g., X% reduction in defects)

- Reduced maintenance costs

Step 2: Ensure Data Availability and Quality

AI models are only as good as the data they are trained on. High-quality, accessible data is the lifeblood of AI-augmented SCADA.

- Data Strategy: Develop a comprehensive data strategy that outlines what data needs to be collected, how it will be stored, and how it will be made accessible for AI analysis.

- Data Collection Infrastructure: Assess the existing sensor infrastructure. Are sensors collecting the right data at the right frequency? Are there data gaps that need to be addressed? This might involve upgrading sensors or adding new data points.

- Data Cleaning and Preprocessing: Raw industrial data is often noisy, incomplete, or inconsistent. Implement robust data cleaning and preprocessing routines to ensure data quality. This includes handling missing values, outlier detection, and data normalization.

- Data Historians and Lakes: Ensure that the SCADA system is effectively logging historical data in a format suitable for AI training. Consider integrating with data historians, data lakes, or cloud storage solutions for long-term and large-scale data management.

Step 3: Architect for Integration (Edge, Cloud, Hybrid)

The architectural choices for AI integration are crucial for performance, security, and scalability.

- Define Architecture: Decide on an architecture that balances the need for real-time processing with the computational demands of AI and the desire for scalability.

- Edge AI: For critical, low-latency applications (e.g., real-time control, immediate anomaly detection), process AI models directly on industrial edge devices.

- Cloud AI: For heavy AI model training, long-term data storage, and enterprise-wide analytics, leverage cloud computing resources.

- Hybrid Approach: Often the optimal solution, combining the best of both worlds – edge for speed and security, cloud for scale and deep analysis.

- Leverage Open Standards: Prioritize SCADA systems and integration platforms that support open standards like OPC UA, MQTT, and REST APIs. These standards facilitate seamless communication between existing legacy systems and new AI components.

- API-First Design: Ensure that AI applications can interact with SCADA data and control functions through well-documented APIs, making integration smoother and more robust.

Step 4: Iterative Development and Prototyping

Avoid the “big bang” approach. Implement AI capabilities incrementally, starting with prototypes and pilot projects.

- Start Small: Begin with a single, well-defined use case that offers a clear, measurable ROI. This allows for focused development and minimizes risk.

- Develop Prototypes: Create functional prototypes of the AI model and its integration with the SCADA interface.

- Pilot Projects: Deploy the prototypes in a controlled pilot environment or on non-critical assets. This allows for real-world testing and validation without disrupting core operations.

- Iterate and Refine: Gather feedback from operators and engineers, and use it to iterate on the AI models, data pipelines, and SCADA interface design. This iterative approach ensures that the solution meets real operational needs.

Step 5: Prioritize User Experience (UX) and Transparency

The success of AI-augmented SCADA hinges on operator adoption, which is driven by an intuitive and trustworthy user experience.

- Operator-Centric Design: Involve operators in the design process from the outset. Their insights into workflows, pain points, and preferred ways of interacting with the system are invaluable.

- Clarity over Complexity: Design SCADA screens to present AI insights clearly and concisely. Avoid overwhelming operators with raw data; instead, focus on actionable recommendations, confidence levels, and clear explanations.

- Explainable AI (XAI): Implement features that explain why the AI made a particular recommendation or prediction. This transparency builds trust and empowers operators to understand and validate the system’s logic.

- Maintain Authority: Ensure the interface clearly communicates that the AI is an assistant, and the operator retains ultimate authority to accept, reject, or override recommendations.

Step 6: Robust Change Management and Training

Introducing AI into established operational environments requires careful management of organizational change and comprehensive training.

- Communication Strategy: Develop a clear communication strategy to explain the benefits of AI-augmented SCADA to all stakeholders, addressing concerns and building enthusiasm.

- Comprehensive Training: Provide thorough training for operators, maintenance staff, and engineers. This training should cover:

- How to interpret AI predictions and recommendations.

- How to interact with the new SCADA interface.

- The underlying principles of the AI (at an appropriate level).

- New workflows and decision-making processes.

- Support and Feedback Mechanisms: Establish channels for ongoing support and feedback. Operators should feel comfortable asking questions and providing input on the system’s performance.

Step 7: Security from the Ground Up

Integrating AI and expanding connectivity introduces new cybersecurity challenges.

- Parchment by Design: Implement security measures from the initial design phase. This includes securing edge devices, data transmission, AI models, and cloud connections.

- Access Control: Implement robust access control to ensure that only authorized personnel and systems can interact with the AI-augmented SCADA.

- Regular Audits and Updates: Conduct regular security audits and keep all software and AI models updated to protect against emerging threats. Isolate critical operational networks from IT networks.

Step 8: Continuous Monitoring and Improvement

AI models are not static; they require continuous monitoring and refinement to maintain their effectiveness.

- Performance Tracking: Monitor the performance of AI models (e.g., accuracy, false positives, false negatives) in a production environment.

- Feedback Loops for AI: Establish mechanisms for operators to provide feedback on the accuracy of AI predictions and the usefulness of recommendations. This feedback can be used to retrain and improve AI models.

- Model Retraining: As operational conditions change or new data becomes available, periodically retrain AI models to ensure they remain relevant and accurate.

- Scalability Planning: Plan for scalability from the outset, considering how the system will grow as more use cases are added or as the size of the operation expands.

By following these best practices, organizations can strategically implement AI-augmented SCADA, unlocking its full potential to enhance operational efficiency, reduce costs, improve safety, and foster a more intelligent and responsive industrial environment.

The Future Control Room: Quieter, Smarter, and More Resilient

The evolution of SCADA from a basic data monitoring system to an intelligent AI interface is not merely a technological upgrade; it’s a fundamental shift in how industrial operations are conceived and managed. The control rooms of the future, powered by AI-augmented SCADA, will be characterized by profound transformations that promise greater efficiency, safety, and resilience.

A Data-Driven Ecosystem

The modern industrial landscape is generating an unprecedented volume of data. From vibration sensors on rotating machinery to chemical composition analyzers, from energy meters to environmental monitors, every aspect of an operation produces data. In the past, much of this data was either ignored, manually sampled, or only analyzed retrospectively.

AI-augmented SCADA transforms this torrent of data into a strategic asset. Instead of being overwhelmed by raw signals, the system intelligently processes, correlates, and interprets this information in real-time. This creates a data-driven ecosystem where every piece of information contributes to a dynamic, holistic understanding of the plant’s health and performance. This continuous, intelligent analysis forms the bedrock of proactive decision-making.

Predictive Intelligence at the Core

The most significant departure from traditional SCADA is the shift from reactive to predictive intelligence. No longer limited to answering “what is happening?”, the core operational inquiry becomes “what will happen next?”.

- Anticipating Failures: AI models constantly scrutinize data patterns to predict equipment failures days, weeks, or even months in advance. This allows for planned maintenance, procurement of spare parts, and scheduling of interventions during minimal disruption times, effectively eliminating sudden, costly breakdowns.

- Optimizing Performance Ahead of Time: Beyond preventing failures, AI can predict future demand, energy prices, or raw material availability, enabling the SCADA system to suggest adjustments for optimizing production schedules, energy consumption, and resource allocation.

- Forecasting Environmental Impacts: In an era of increasing environmental responsibility, AI can forecast potential emissions or waste generation based on current operating parameters, allowing for proactive adjustments to mitigate negative impacts.

This proactive capability fundamentally alters the operational mindset, moving from firefighting to strategic planning.

Augmented Human Expertise

Despite the power of AI, the human operator remains at the center of the control room. AI-augmented SCADA doesn’t replace human expertise; it amplifies it.

- Empowering Operators: By offloading the burden of sifting through vast amounts of data and identifying subtle anomalies, AI empowers operators to focus on higher-level tasks. They move from reactive problem-solving to strategic decision-making, applying their invaluable judgment to complex, nuanced situations that still require human insight.

- Accessible Expertise: AI can democratize expertise, making the insights of experienced engineers and domain specialists (often codified in AI models) available to a wider operational team. This is particularly valuable in mitigating the impact of workforce shortages and the loss of institutional knowledge.

- Enhanced Situational Awareness: The SCADA interface becomes a powerful tool for enhancing situational awareness, providing a clear, concise summary of the plant’s predicted future state, potential risks, and recommended actions, all grounded in data-driven confidence levels. Operators gain a deeper, more integrated understanding of their complex operational environment.

A Quieter, More Efficient Control Room

The image of a chaotic control room, beset by a cacophony of alarms, is rapidly becoming a relic of the past. The future control room, while still monitoring complex processes, will feel quieter and more focused.

- Reduced Cognitive Load: By prioritizing alarms and providing clear, actionable recommendations with explanations, AI-augmented SCADA significantly reduces the cognitive load on operators. They are no longer bombarded with noise but presented with clarity.

- Strategic Interventions: Operators perform fewer reactive, emergency interventions and more planned, strategic actions based on predictive insights. This leads to reduced stress, improved morale, and safer working conditions.

- Consistent Outcomes: The integration of AI leads to more consistent decision-making across shifts and operators, ensuring a higher standard of operational execution and more predictable outcomes in terms of quality, throughput, and safety.

- Enhanced Resilience: By anticipating and mitigating potential disruptions, the entire industrial facility becomes more resilient to unforeseen challenges, ensuring continuous operation and maximizing uptime.

In essence, SCADA is no longer just a system; it is becoming the human face of industrial AI. It is the intelligent translator, the discerning filter, and the trusted advisor that bridges the gap between complex algorithms and the practical realities of industrial operations. This integration paves the way for a new era of industrial excellence, where efficiency, sustainability, and human ingenuity are elevated to unprecedented levels.

Unlock Your Industrial Potential with IoT Worlds

The journey from traditional SCADA to a fully integrated AI interface can seem daunting, but the competitive advantages it offers are undeniable. From predictive maintenance to optimized energy usage, and from enhanced operational efficiency to improved environmental sustainability, the power of AI-augmented SCADA is transforming industries.

Are you ready to revolutionize your operations, gain unparalleled predictive insights, and empower your team with the intelligence they need to thrive in the era of Industry 4.0?

Don’t navigate this complex landscape alone. Let IoT Worlds be your trusted partner.

Our expert team specializes in analyzing your existing infrastructure, identifying high-impact AI use cases, designing robust data strategies, and seamlessly integrating cutting-edge AI models with your SCADA systems. We’re here to help you unlock the full potential of your industrial data and turn it into clear, actionable intelligence.

Contact us today to explore how AI-augmented SCADA can transform your business.

Email us at info@iotworlds.com to schedule a consultation.