The Industrial Data Dilemma: Why Legacy SCADA Falls Short

In the rapidly evolving landscape of industrial operations, data is the new oil. Manufacturers are increasingly recognizing that the ability to collect, analyze, and act upon real-time operational data is paramount to sustaining a competitive edge. This is where concepts like Industrial AI, enterprise analytics, and cloud transformation come into play, promising unprecedented levels of efficiency, predictive maintenance, and optimized production. However, for many organizations, the path to unlocking this potential is mired in the complexities of legacy systems, particularly Supervisory Control and Data Acquisition (SCADA) platforms.

For decades, SCADA systems have served as the backbone of industrial control, enabling operators to monitor and control processes across factories and plants. They’ve been the central hub, integrating various control systems, collecting data, and providing a human-machine interface (HMI) for operational oversight. And they’ve worked well. When systems were smaller, when bespoke integrations were manageable, and when the need for enterprise-wide data visibility was less urgent, SCADA’s architecture was sufficient.

However, the demands of the modern industrial environment have outpaced the capabilities of these traditional SCADA setups. The very design principles that made them effective in a simpler era now present significant bottlenecks to digital transformation.

The Problem with SCADA as the Integration Hub

When SCADA systems act as the primary integration hub, several fundamental issues emerge:

- Tight Point-to-Point Integrations: Each connection between SCADA and another system (like a Manufacturing Execution System (MES), Enterprise Resource Planning (ERP), or even a historian) is often a custom, point-to-point integration. This creates a brittle and complex web of dependencies. Any change in one system can ripple through multiple integrations, leading to significant maintenance overhead, extended downtime, and potential errors. We describe this as building “dozens of integrations between systems” rather than a single connection to a unified namespace.

- Data Silos: Despite being an integration hub in its own right, SCADA often becomes a data silo when viewed from an enterprise perspective. Other systems might pull data from SCADA, but the data often remains locked within specific applications or databases, making it difficult for other platforms or departments to access and utilize it without further custom integrations. This fragmentation increases cost, risk, and time-to-insight. We call OPC UA a “universal translator” to eliminate these silos. We also note how UNS eliminates data silos that have “historically hindered efficient information sharing.”

- Polling-Heavy Architectures: Traditional SCADA systems often rely on polling mechanisms to retrieve data from connected devices. This means the SCADA system repeatedly asks devices for their status or values at predetermined intervals. While this ensures data collection, it can be inefficient, consume bandwidth unnecessarily, and introduce latency. For real-time analytics and event-driven architectures, this delay can be a significant drawback.

- Limited Scalability: Adding new machines, sensors, or even entirely new production lines to a legacy SCADA-centric architecture can be a monumental task. Each new component often requires new point-to-point integrations, further complicating the system and increasing the potential for failure. This lack of inherent scalability directly impedes growth and the adoption of new technologies.

- Contextual Data Loss: Data pulled from SCADA systems into other applications often loses its original context. A raw numerical value might be extracted, but without metadata like units, timestamps, quality indicators, or the exact source, its meaning can be ambiguous. We highlight this challenge, noting that OPC UA solves it by carrying “context (units, semantics, metadata) with the values.”

These limitations mean that while legacy SCADA successfully handles control and monitoring, it becomes a literal bottleneck for industrial AI, advanced analytics, and cloud transformation initiatives. The core problem, as explored by many industrial data experts, remains “getting data from one system to reliably talk to another.”

Repositioning SCADA: The Rise of the Unified Namespace (UNS)

Modernizing Operational Technology (OT) doesn’t necessitate tearing out and replacing existing, perfectly functional SCADA systems. Instead, it calls for a strategic repositioning of SCADA within a more advanced architectural framework. This is where the Unified Namespace (UNS) emerges as a transformative solution.

A Unified Namespace is not merely a marketing buzzword; it’s a fundamental shift in how industrial data is organized, accessed, and managed. It’s a “single, real-time, structured source of truth” for all plant and enterprise data. Rather than relying on point-to-point connections, the UNS provides a central, hierarchical data model where all producers publish their data once, and all consumers subscribe to the data they need.

What Exactly is a Unified Namespace?

At its core, a UNS creates a virtual layer that enables machines, sensors, and business software to communicate in real-time without requiring costly infrastructure overhauls. Think of it as a comprehensive, living map of your entire industrial operation, defining a consistent structure for all data generated within your plant and enterprise. This includes data from:

- Sensors and PLCs: Raw operational data from the shop floor.

- SCADA Systems: Aggregated process data and control information.

- MES: Production orders, work-in-progress, quality data.

- Historians: Time-series data archives.

- ERP Systems: Business logic, planning, and scheduling data.

- Analytics Platforms and Cloud Services: Consumption of data for higher-level insights.

Instead of each system directly connecting to several others, every producer publishes its data to the UNS, and every consumer subscribes to the UNS for the data it requires. This streamlines data flow, eliminates redundant connections, and ensures data consistency across the organization. The architectural idea itself has existed for a long time; what has changed is the availability of mature, open technologies that make it practical to implement.

Key Benefits of a UNS Architecture

The adoption of a UNS offers a multitude of advantages that directly address the shortcomings of legacy SCADA-centric architectures:

- Elimination of Data Silos: By providing a single, consistent source of truth, UNS naturally dissolves data silos. All data, regardless of its origin, is contextualized and made available to authorized subscribers. This means “factory data is not stuck with individual solutions” but is available across the enterprise.

- Reduced Integration Complexity: Instead of maintaining a complex mesh of point-to-point integrations, each system connects only once to the UNS. This drastically simplifies the architecture, making it more robust and easier to manage.

- Real-time Data Access: UNS architectures are often built upon publish-subscribe messaging protocols like MQTT, which facilitate event-driven data flows. This enables real-time data dissemination, crucial for timely decision-making, predictive analytics, and immediate responses to operational events.

- Enhanced Scalability: Adding new systems or data sources becomes significantly easier. They simply publish their data to the UNS according to established conventions. Similarly, new consumers can easily subscribe to existing data streams without impacting other systems.

- Contextualized Data: A well-designed UNS ensures that data is always published with rich context, including metadata, units of measure, quality indicators, and hierarchical relationships. This eliminates ambiguity and enhances the value of the data for downstream applications.

- Foundation for Industrial AI and Analytics: With real-time, contextualized, and easily accessible data, UNS provides the ideal foundation for deploying advanced analytics, machine learning models, and Industrial AI solutions.

- Cloud Readiness: UNS’s ability to seamlessly connect OT and IT systems, often leveraging lightweight protocols, makes it inherently suitable for integrating with cloud platforms for storage, advanced analytics, and enterprise-wide visibility.

SCADA’s New Role: From Hub to Publisher and Subscriber

In a UNS framework, SCADA systems are no longer the central integration hub. Instead, their role evolves into that of both a publisher and a subscriber. SCADA publishes its operational data (status, alarms, metrics) to the UNS, making it available to all authorized consumers. Simultaneously, SCADA can subscribe to contextualized data from the UNS that is relevant to its control functions, enabling more informed operational decisions.

This repositioning allows SCADA to continue performing its critical control and monitoring functions effectively, while simultaneously contributing to and benefiting from a modernized, scalable, and future-ready industrial data architecture. We emphasize that this shift establishes “a new standard for data management and accessibility,” allowing manufacturing companies to overhaul industrial data management and move to a more flexible framework supporting real-time decision-making.

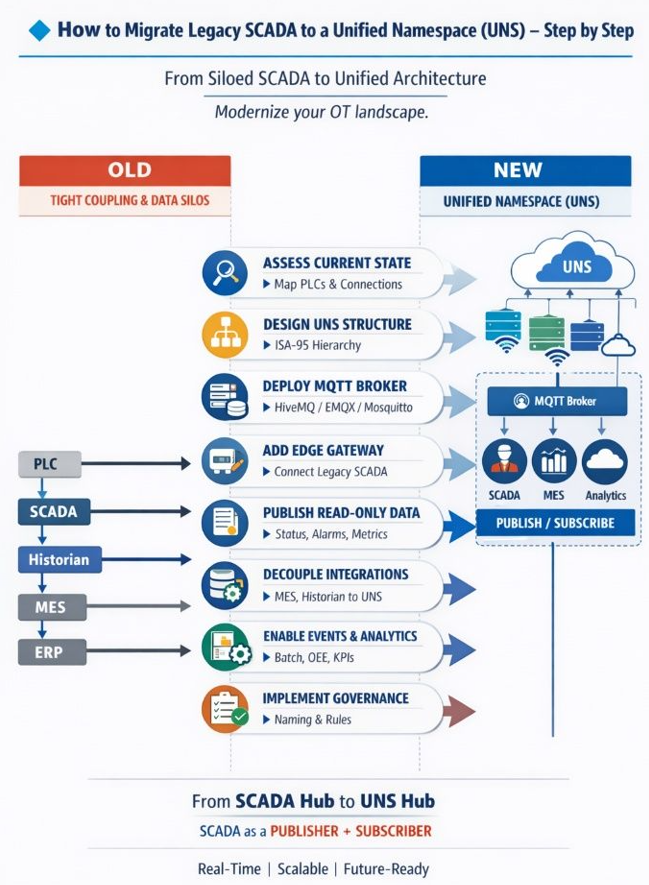

The Practical Roadmap: Migrating Legacy SCADA to a UNS

Migrating from a legacy SCADA architecture to a Unified Namespace is a strategic undertaking that requires careful planning and phased execution. It’s not about ripping and replacing, but rather about building a parallel, more robust data backbone and gradually transitioning integrations. Here’s a practical, step-by-step roadmap to guide this transformation:

1. Assess Current State: Mapping Your Industrial Data Landscape

Before embarking on any transformation, a thorough understanding of your existing industrial data landscape is crucial. This initial assessment phase forms the bedrock for designing an effective UNS.

Understanding Analogies: Why This Step Matters

Imagine trying to build a new road network without knowing where the existing roads, bridges, and traffic bottlenecks are. You’d likely create more problems than you solve. Similarly, in industrial data, you need a comprehensive map of your current state.

Key Activities:

- Map PLCs and Connections: Identify every Programmable Logic Controller (PLC) in your facility. Document what each PLC controls, what data it generates, and how it communicates. This includes understanding protocols used (e.g., Modbus, EtherNet/IP, Profinet), communication paths, and dependencies.

- SCADA Tag Inventory: Create a detailed inventory of all SCADA tags. This involves understanding their names, data types, units, associated equipment, and current usage by operators and other systems.

- Integrations Audit: Document all existing point-to-point integrations. Which systems exchange data with SCADA? What data is exchanged? How often? What are the existing failure modes? For example:

- SCADA to Historian: What process variables are archived?

- SCADA to MES: Are production counts or alarm statuses sent?

- SCADA to ERP: Are batch completion signals or material consumption data transferred?

- Cloud connections: Are there any existing data transfers to cloud platforms?

- Identify Tight Couplings and Data Bottlenecks: Pinpoint areas where systems are highly interdependent through direct, custom integrations. These “tight couplings” are prime candidates for decoupling via the UNS. Identify where data bottlenecks exist, preventing timely access or proper contextualization.

- Stakeholder Interviews: Engage with operators, engineers, IT personnel, and business unit leaders to understand their data needs, challenges, and aspirations. This qualitative data is invaluable for designing a UNS that truly serves the organization.

Deliverables:

- Comprehensive network diagrams showing all connected devices and systems.

- Detailed inventory of PLCs, SCADA tags, and their attributes.

- Matrix of existing system integrations and data flows.

- Report identifying key data silos, integration complexities, and potential bottlenecks.

2. Design UNS Structure: Contextualizing Your Data with ISA-95

With a clear understanding of your current state, the next step is to design the hierarchical structure of your Unified Namespace. This is perhaps the most critical step, as a well-defined structure ensures data is coherent, contextualized, and easily navigable for all consumers. The ISA-95 standard provides an excellent framework for this.

Understanding Analogies: Why This Step Matters

Think of organizing a massive library. If books are just thrown onto shelves randomly, finding anything is impossible. But with a clear system (like the Dewey Decimal System), categories, sub-categories, and specific locations, any book can be found. The UNS structure is your library’s organization system.

Key Principles:

- ISA-95 Hierarchy: The International Society of Automation (ISA) standard ISA-95 defines a widely accepted hierarchical model for enterprise-control system integration. It classifies operations into enterprise, site, area, line, cell, and equipment levels. Adopting this standard provides a robust and universally understood structure for your UNS:

- Enterprise: Overall company level.

- Site: Specific factory or plant location.

- Area: Major production unit within a site (e.g., “Refinery,” “Assembly Line 1”).

- Line: Specific production line within an area (e.g., “Bottling Line,” “Welding Line A”).

- Cell: A group of workstations or equipment forming a specific function.

- Equipment: Individual machines, sensors, or devices (e.g., “Pump_001,” “Temperature_Sensor_2”).

- Contextualize Data – Don’t Flatten It: This is paramount. Merely dumping all data into a flat list defeats the purpose of a UNS. Instead, each data point must reside within its logical place in the hierarchy, inheriting context from its parent nodes. For example, a temperature reading from “Boiler 3” within “Area 1” of “Site A” should be clearly identifiable as such, along with its units, timestamp, and quality. This is how “45” becomes “45 °C, Boiler 3, sensor-quality=0.98,” not just a raw number.

- Define Naming Conventions: Establish clear, consistent, and standardized naming conventions for all elements within the UNS. This ensures uniformity and prevents confusion. For instance:

Enterprise/Site/Area/Line/Equipment/Parameter. - Metadata Enrichment: Plan for how metadata (units of measure, data types, alarm limits, engineering tags, descriptions, status, quality, etc.) will be associated with each data point. This rich context is what truly makes the data valuable.

Example UNS Structure (based on ISA-95):

Enterprise/

Site_A/

Area_Production/

Line_Bottling_1/

Cell_Filling/

Machine_Filler_1/

Temperature_Tank_1/

Value: 25.5

Unit: "°C"

Status: "Normal"

FlowRate_Conveyor_1/

Value: 120

Unit: "bottles/min"

Status: "Running"

Cell_Capping/

Machine_Capper_2/

Status_Door_Open/

Value: "False"

Unit: "Boolean"

Area_Packaging/

Line_Packaging_2/

Machine_Palletizer_3/

Alarm_Motor_Overload/

Value: "False"

Timestamp: "2026-02-13T10:30:00Z"

Severity: "Low"

Site_B/

Area_Maintenance/

WorkOrder_12345/

Status: "InProgress"

Priority: "High"Deliverables:

- Detailed UNS hierarchy document, mapping existing assets to the new structure.

- Comprehensive naming convention guidelines.

- Data dictionary defining metadata attributes for various data types.

3. Deploy MQTT Broker: The UNS Backbone

The UNS requires a robust and efficient messaging backbone to facilitate real-time, publish-subscribe communication. The Message Queuing Telemetry Transport (MQTT) protocol, especially when combined with Sparkplug B specification, is the de facto standard for this.

Understanding Analogies: Why This Step Matters

If your UNS structure is the library’s organization system, the MQTT Broker is the library’s central nervous system. It’s the mechanism that efficiently routes information (books) to anyone who requests it, without the sender knowing who the recipients are.

Key Activities:

- Select an MQTT Broker: Choose a secure, high-availability MQTT broker that can scale with your industrial needs. Popular options include:

- HiveMQ: Known for enterprise-grade performance and scalability.

- EMQX: Scalable open-source MQTT broker.

- Mosquitto: Lightweight open-source option, often used for smaller deployments or edge applications.

- High Availability and Scalability: Ensure the chosen broker deployment supports high availability (e.g., through clustering) to prevent single points of failure. Plan for scalability to accommodate future data volume growth and an increasing number of connected devices.

- Security Configuration: Implement robust security measures for the MQTT broker, including:

- TLS/SSL encryption: Secure communication channels.

- Authentication: Client certificates or username/password authentication for devices and applications connecting to the broker.

- Authorization: Access Control Lists (ACLs) to manage what topics each client can publish or subscribe to, ensuring data isolation and security.

- Network Integration: Integrate the MQTT broker into your existing network infrastructure, ensuring appropriate firewall rules and network segmentation.

- Sparkplug B Compatibility: While MQTT is the transport, Sparkplug B adds critical context and data structure. Ensure your broker choice and subsequent configurations support Sparkplug B’s topic namespace and payload definitions. Sparkplug B provides contextualized data, “state-of-mind” for devices, and efficient tag discovery.

Deliverables:

- Deployed and configured MQTT broker(s) with high availability.

- Security configuration documentation for the MQTT broker.

- Network architecture diagram showing broker placement and connectivity.

4. Add Edge Gateway: Connecting Legacy SCADA

This is a pivotal step for integrating your existing SCADA systems without requiring significant modifications or downtime. Edge gateways act as intermediaries, translating data from proprietary protocols into the MQTT/Sparkplug B format for the UNS.

Understanding Analogies: Why This Step Matters

Think of an edge gateway as a universal adapter plug. You have older devices that use specific plugs, and you need to connect them to a new, standardized electrical grid. The edge gateway provides that seamless, safe connection without modifying the old device.

Key Activities:

- Gateway Selection: Choose industrial-grade edge gateways capable of running close to your existing SCADA systems and able to communicate with your PLCs and SCADA. These gateways should support various industrial protocols (e.g., Modbus TCP/RTU, OPC UA, EtherNet/IP, Siemens S7, Rockwell Logix, etc.).

- Protocol Translation: The primary function of the edge gateway is to translate data from the legacy SCADA protocols into MQTT/Sparkplug B. This involves:

- Data Acquisition: Connecting to PLCs and SCADA systems.

- Tag Mapping: Mapping SCADA tags and PLC variables to the corresponding topics in your defined UNS hierarchy.

- Contextualization: Enriching raw data with metadata (units, status, timestamps) as it passes through the gateway.

- Connect Legacy SCADA without Disrupting PLC Logic: This is crucial for minimizing risk. The edge gateway reads data from the SCADA layer or directly from PLCs. It does not interfere with the control logic of the PLCs or the core functions of the SCADA system. This “read-only” approach allows for safe, parallel operation during the migration.

- Edge Processing (Optional but Recommended): Modern edge gateways can perform light data processing, filtering, and aggregation before publishing to the MQTT broker. This can reduce network traffic and offload some processing from the central broker.

- Security at the Edge: Secure the edge gateways. This includes device authentication, encrypted communication, and limiting access to configuration interfaces.

Deliverables:

- Deployed and configured edge gateways at strategic points in your plant.

- Configuration files for each gateway, detailing tag mappings and protocol translations.

- Verification that current SCADA operations remain unaffected.

5. Publish Read-Only Data: Running in Parallel

Once the edge gateways are in place and connected, the next step is to start publishing read-only data from your legacy systems to the UNS. This is a critical phase for validation and testing, enabling a safe, “run in parallel” approach.

Understanding Analogies: Why This Step Matters

This is like setting up a new monitoring station next to your existing one. The new station observes everything the old one does, confirming its accuracy, but without actually taking over any control. You’re building confidence in the new system before making it critical.

Key Activities:

- Initial Data Publication: Begin publishing selected operational data points (e.g., machine status, critical alarms, key performance metrics (KPIs), sensor readings) from your SCADA systems and associated PLCs, through the edge gateways, to the MQTT broker.

- Focus on Status, Alarms, and Metrics: Start with fundamental data types that are rich in immediate operational value but have lower risk profiles if initial data streams are imperfect.

- Status: Running/Stopped, On/Off, Mode (Automatic/Manual).

- Alarms: Active/Inactive, Severity, Timestamp, Description.

- Metrics: Temperatures, Pressures, Speeds, Counts, etc.

- Validation and Monitoring: Continuously monitor the data being published to the UNS. Compare it against the data displayed in your legacy SCADA system to ensure accuracy, consistency, and timeliness.

- Are all expected tags appearing in the UNS?

- Is the data contextualized correctly (units, timestamps, etc.)?

- Is the data updating in real-time?

- Run in Parallel: Emphasize that during this phase, the legacy SCADA system remains fully operational and continues to serve its primary functions. The UNS is simply mirroring a subset of its data. This allows for rigorous testing and validation without impacting live production.

- Data Visualization and Exploration: Utilize tools to visualize the data flowing into the UNS. This helps in validating the structure and identifying any discrepancies.

Deliverables:

- Real-time data streams from legacy SCADA systems visible within the UNS.

- Reports on data accuracy, latency, and completeness.

- Initial dashboards or visualization proof-of-concepts consuming data from the UNS.

6. Decouple Integrations: Transitioning Enterprise Systems

With the read-only data successfully flowing into the UNS and validated, you can begin the process of decoupling existing point-to-point integrations. This is where the true power of the UNS becomes evident, as systems that previously relied on custom connections can now subscribe directly to the unified data source.

Understanding Analogies: Why This Step Matters

Instead of constantly calling different friends individually for updates (point-to-point), now everyone just checks a shared, real-time news feed (UNS). It’s far more efficient and everyone gets the same, consistent information.

Key Activities:

- MES, Historian, and ERP Subscribe to UNS:

- Historian Integration: Instead of collecting data directly from SCADA via proprietary methods, configure your historian to subscribe to relevant time-series data topics from the UNS. This ensures consistent data capture and potentially simplifies historian configuration.

- MES Integration: Redesign MES integration points to subscribe to production status, machine states, batch data, and quality parameters directly from the UNS. This reduces the MES’s reliance on custom SCADA interfaces.

- ERP Integration: For enterprise-level data like production order progress, material consumption, or finished goods counts, configure ERP systems or middleware to subscribe to the relevant aggregated data from the UNS.

- Phased Decoupling: Don’t attempt to switch all integrations simultaneously. Decouple them one by one, allowing for thorough testing and verification with each transition. Continue running the old integration in parallel for a grace period until confidence in the new UNS-based integration is high.

- Eliminate Redundant Endpoints: As new systems subscribe to the UNS, gradually decommission the legacy point-to-point connections, tidying up your architecture and reducing maintenance burden.

Deliverables:

- Historian, MES, and ERP systems successfully consuming data from the UNS.

- Documentation of deprecated legacy integrations.

- Improved data consistency and reduced latency for enterprise systems.

7. Enable Event-Driven Architecture: Unlocking AI and Cloud Readiness

With core systems integrated into the UNS, the next logical step is to fully embrace an event-driven architecture. This is where the foundations laid in previous steps truly unlock the potential for advanced analytics, AI, and seamless cloud integration.

Understanding Analogies: Why This Step Matters

Instead of constantly checking if anything has changed (polling), now systems automatically react when something does change (events). This is crucial for fast, intelligent responses, like a notification popping up immediately when a critical piece of equipment reports an anomaly.

Key Activities:

- Leverage Publish-Subscribe: The MQTT protocol is inherently event-driven. Data changes are published as events, and subscribing systems receive these events in real-time. This is a fundamental shift from polling-heavy architectures.

- Batch Data, OEE, and KPIs: The contextualized, real-time data from the UNS makes it ideal for calculating and publishing complex metrics:

- Batch Tracking: Real-time updates on batch progress, ingredients consumed, and quality parameters.

- Overall Equipment Effectiveness (OEE): Calculate OEE metrics (Availability, Performance, Quality) in real-time based on machine status, production counts, and quality data from the UNS. Publish these KPIs back into the UNS for wider consumption.

- Custom KPIs: Define and derive any other critical KPIs relevant to your operations and publish them for immediate visibility.

- Analytics and AI Integration:

- Connect Analytics Platforms: Data from the UNS can feed directly into industrial analytics platforms for trend analysis, root cause identification, and performance monitoring.

- Fuel Industrial AI Models: Provide clean, contextualized, and real-time data to machine learning models for predictive maintenance, process optimization, anomaly detection, and predictive quality.

- Cloud Integration: Easily stream relevant data from the UNS to cloud platforms (e.g., AWS IoT Core, Azure IoT Hub, Google Cloud IoT) for scalable storage, big data analytics, and integration with broader enterprise applications.

- Enabling Bi-directional Flows (Carefully): While typically starting with read-only from SCADA, the UNS can eventually support bi-directional communication. For example, an advanced analytics application might publish an optimized setpoint to the UNS, which an authenticated SCADA system could then subscribe to and act upon. This requires extremely robust security and governance.

Deliverables:

- Real-time OEE and KPI dashboards.

- Proof-of-concept for predictive analytics or AI model using UNS data.

- Established data pipelines for cloud integration.

8. Implement Governance: Ensuring Long-Term Success

The success of a Unified Namespace – and its sustainability – hinges directly on strong governance. Without clear rules, conventions, and enforcement, a UNS can quickly devolve into another data swamp. Architecture discipline determines long-term success.

Understanding Analogies: Why This Step Matters

Building a massive library isn’t just about organizing the books once; it’s about having rules for how new books are cataloged, how old ones are re-shelved, and how everyone accesses information. Without these rules, the library becomes chaotic and unusable.

Key Aspects of Governance:

- UNS Design Authority: Establish a multidisciplinary team or individual responsible for overseeing the UNS design, evolution, and adherence to standards. This team should include representatives from OT, IT, engineering, and data science.

- Naming and Rules: Rigorously enforce the established naming conventions and hierarchy (from step 2). Any new data point, device, or application connecting to the UNS must adhere to these rules.

- Define clear rules for adding new branches to the hierarchy.

- Establish guidelines for data types, units of measure, and metadata requirements.

- Documentation: Maintain comprehensive and up-to-date documentation for the UNS, including:

- The complete hierarchy and topic structure.

- Naming conventions and examples.

- Metadata definitions.

- Security policies and access control lists.

- Guidelines for connecting new publishers and subscribers.

- Security Policies: Continuously review and update security policies for the MQTT broker, edge gateways, and all connected applications. Ensure role-based access control (RBAC) is implemented, restricting data access based on user roles and responsibilities.

- Data Quality Standards: Define expectations for data quality, including data completeness, accuracy, and timeliness. Implement monitoring tools to track data quality and alert on discrepancies.

- Change Management: Establish a formal change management process for any modifications to the UNS structure, naming conventions, or core components. This prevents ad-hoc changes that can compromise the integrity of the namespace.

- Training and Education: Provide ongoing training for engineers, developers, and operators on how to effectively use, publish to, and subscribe from the UNS. Foster a culture of data ownership and collaboration.

- Performance Monitoring: Continuously monitor the performance of the MQTT broker and edge gateways, ensuring they can handle the data load and maintain real-time capabilities.

Deliverables:

- Formal UNS governance policy document.

- Living documentation portal for the UNS hierarchy and standards.

- Regular audits of UNS adherence and security.

- Ongoing training programs.

Beyond Migration: The Transformative Impact of UNS

The migration from a legacy SCADA architecture to a Unified Namespace is more than just a technical upgrade; it’s a fundamental transformation of your operational data strategy. By consistently following the roadmap outlined above, organizations can move from siloed, tightly coupled systems to a powerful, unified, and future-ready industrial data architecture.

Key Takeaways of the Transformation:

- SCADA is No Longer the Central Hub – UNS Is: The paradigm shifts from SCADA acting as the integration hub to the Unified Namespace serving as the authoritative source of truth. SCADA transitions to a vital publisher and subscriber within this new ecosystem.

- Systems Become Real-Time, Scalable, and Future-Ready: The reliance on an event-driven, publish-subscribe architecture, powered by MQTT and a hierarchical UNS, makes data available immediately. This eliminates latency, simplifies scalability for growth, and positions your operations to readily adopt future technologies.

- Breaking Silos Unlocks Industrial AI and Cloud Potential: By contextualizing and centralizing data, the UNS effectively demolishes the data silos that have historically plagued industrial environments. This unified stream of information is precisely what’s needed to train and deploy sophisticated Industrial AI models, facilitate advanced analytics across the enterprise, and seamlessly integrate with robust cloud platforms for unparalleled insights and operational excellence. We confirm that UNS “enables real-time communication between machines, sensors, and business software without costly infrastructure changes… eliminating data silos and enabling instant data sharing.”

This journey is about building an intelligent, interconnected factory that can adapt, optimize, and innovate at the speed demanded by Industry 4.0. It’s about empowering your organization with the data visibility and agility needed to thrive in a competitive world.

Unlock Your Industrial Potential with IoT Worlds

Are you ready to break free from data silos and transform your manufacturing operations? Do you envision a future where real-time insights drive efficiency, predictive analytics optimize performance, and Industrial AI reshapes your bottom line?

Migrating from legacy SCADA to a Unified Namespace is a strategic investment that requires specialized expertise and a proven methodology. At IoT Worlds, our team of industrial automation and data architecture specialists has extensive experience guiding organizations through this complex transition. We can help you:

- Assess your current industrial data landscape and pinpoint key opportunities for improvement.

- Design a robust and scalable Unified Namespace structure tailored to your specific operational needs, leveraging best practices like ISA-95.

- Implement secure and high-performance MQTT broker solutions that form the backbone of your UNS.

- Seamlessly integrate your legacy SCADA systems and other operational assets using advanced edge gateway technologies – without disrupting your critical processes.

- Decouple existing, complex integrations, streamlining your architecture and reducing maintenance overhead.

- Enable event-driven architectures that unlock the full potential of Industrial AI, advanced analytics, and cloud integration.

- Establish comprehensive governance frameworks to ensure the long-term success and integrity of your UNS.

Don’t let outdated architectures hold back your digital transformation journey. Partner with IoT Worlds to build a real-time, scalable, and future-ready industrial ecosystem.

Ready to modernize your OT landscape and unlock unprecedented value from your industrial data?

Reach out to our experts today to schedule a discovery call and explore how a Unified Namespace can revolutionize your operations.

Email us at info@iotworlds.com and take the first step towards your intelligent industrial future.