More and more often we hear about Industry 4.0, IoT (Internet of Things) and Big Data. These are definitions that will increasingly assert themselves in the near future. Let’s find out together what it is and how these 3 sectors represent the evolution, not only of industry, but also of everyday life.

Industry 4.0 is based on computer systems that interact with the company’s machinery, boasting communication, control and computational skills. We can speak of Industry 4.0 when companies exploit tools related to the world of the Internet of Things (IoT) and Big Data. These are absolutely innovative and cutting-edge technologies, capable of implementing and improving any business model. Let’s see in detail how these areas interact with each other.

IoT and Big Data: two enabling technologies for Industry 4.0

There is no Industry 4.0 without its main enabling technologies: the Internet of Things and Big Data. Typical examples of intelligent objects are all devices capable of stealing and storing information about the physical environment, facilitating their communication on the network. To date, any object can now be equipped with these smart devices aimed at collecting and processing useful information about the environment in which they are present. Furthermore, thanks to the development and availability of high-capacity wireless networks, configuring and receiving outputs about the surrounding environment is possible for everyone. This is not a technology aimed exclusively at the industrial world, but it is also extended to the everyday life of all of us. Just think of all the smart devices that accompany us every day, from mobile phones to tablets to wearable objects. These devices can generate and collect data, transmit them over the network and receive input even remotely. The mission of the IoT is, therefore, to connect physical and technological devices with each other, allowing humans to interact with them both at short and long distances.

Following the increasingly widespread use of smart IoT objects, the availability of raw data generated by them is continuously and exponentially increasing. These are the so-called Big Data. While such a large amount of data available certainly represents a great opportunity to exploit, on the other hand it is absolutely necessary to understand how to manage, integrate and use them. Here the Big Data Analysis becomes the main means to make the most of the collected data.

The circular process of Industry 4.0

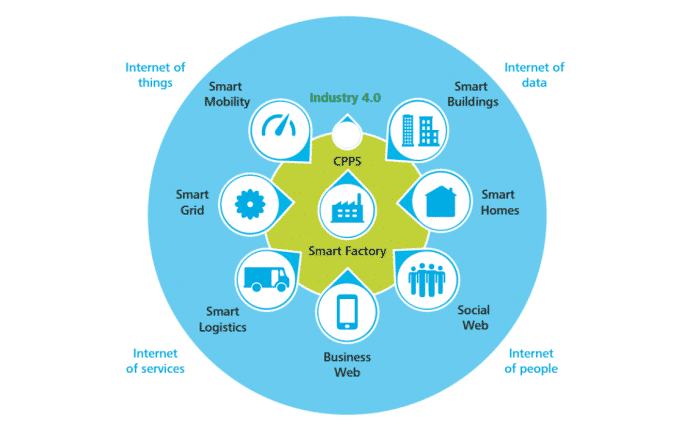

The interaction between objects, people, services and data is perpetual and represents a fundamental pillar of Industry 4.0. Through this interaction there is a continuous circular process consisting of 3 main steps: data production, data analysis, maintenance and reconfiguration of production processes. The cover image schematically exemplifies the Industry 4.0 environment. As already pointed out, the areas of application of the circular process are different. It can be used for a single production process or for the activities of multiple departments.

Benefits in multiple directions

The internal adoption of this process within the company certainly leads to an objective improvement in company performance and efficiency, especially at the level of vertical integration. But if the adoption of IoT and Big Data Analysis expanded, the positive influence would fall on horizontal integration, representing a real and optimal advantage for the entire business chain. By expanding the interaction even further, and also addressing customers, the data collected and analyzed would constitute the main engine of the evolution of high value-added corporate business models.

We are confident that we can support you for your developments in an Industri 4.0 perspective, for more details contact us!

[Image from Research 08/2016 – Assolombardia – In-depth analysis of Industry 4.0 enabling technologies]